10. The non-return valve¶

A non-return valve, also called a check valve, has the task of allowing the passage of pressurized air in one direction and completely cutting off the passage of pressurized air in the opposite direction.

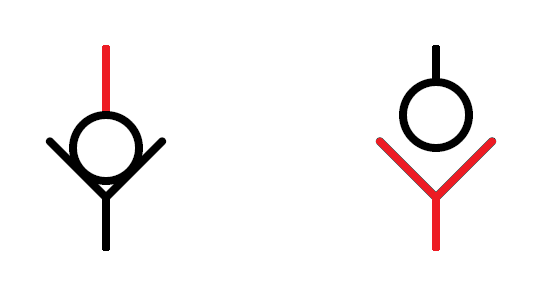

Their position is usually what appears in the following symbols, so these valves allow the circulation of pressurized air upwards and cut off the passage of pressurized air downwards:

Symbols of the closed and open non-return valve.¶

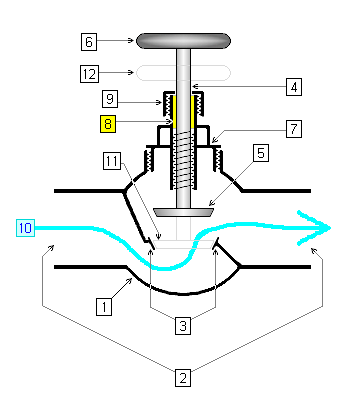

The internal construction of these valves is made with a sphere and a cone like that of a funnel into which the sphere fits.

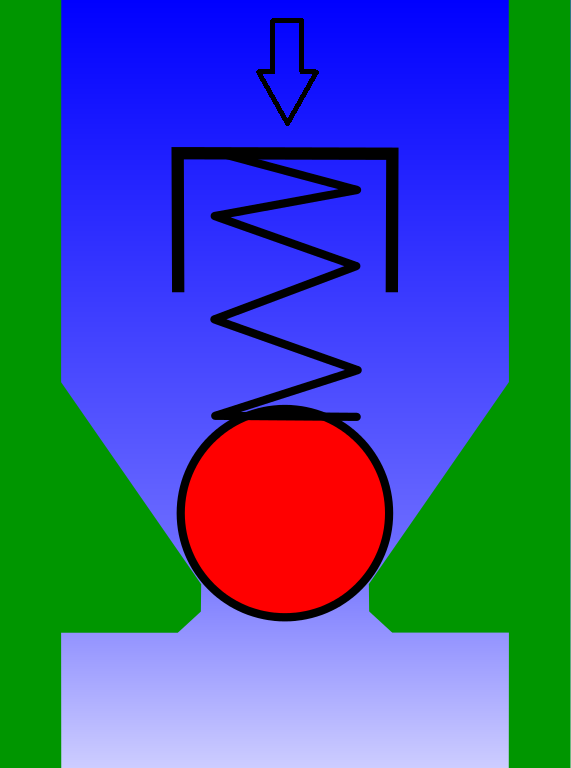

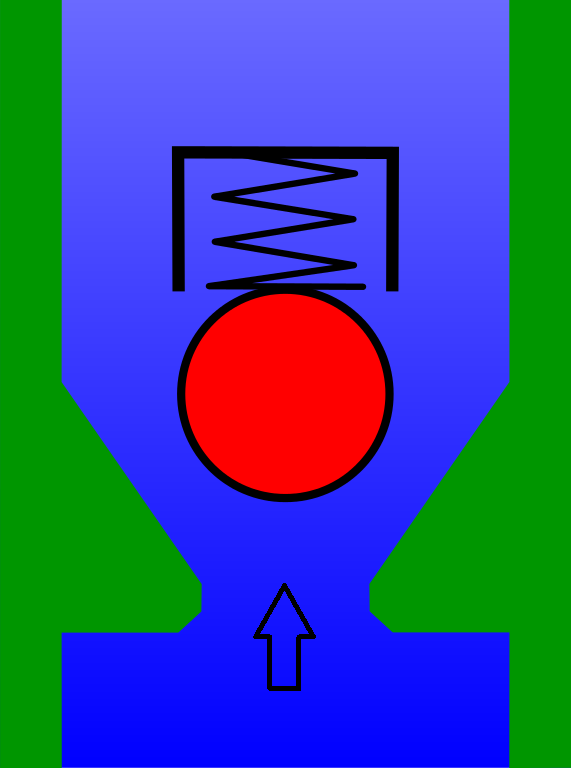

When the pressurized air arrives from above, the sphere locks in the funnel thanks to the pressure of the spring and the pressurized air itself. In this position the sphere does not allow air to pass downwards:

When the pressurized air arrives from below, the sphere is lifted by the air pressure (much greater than the force of the spring) allowing the pressurized air to circulate upwards:

The choke valve¶

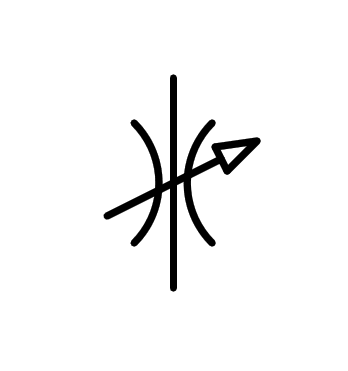

This valve, also called a flow regulator, is a valve that partially closes the passage of pressurized air to allow only part of the entire air flow to circulate.

Its function is the same as that of a water tap, which allows controlling the water jet with greater or lesser flow, but applied to pressurized air.

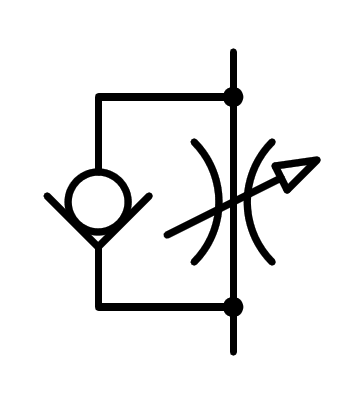

Symbol of a throttle or flow regulating valve.¶

Internally, the valve is made up of a screw that brings a plug closer or further away from the pressurized air opening. The closer the plug is to the opening, the less air flow it will allow to pass through.

Internal view of a throttle or flow regulating valve.¶

One-way throttle valve¶

This valve is made up of the two previous valves in parallel. Its function is to allow free passage of pressurized air in one direction and throttle the passage of pressurized air in the opposite direction.

Symbol of a one-way throttle valve.¶

This valve is normally used to allow the free passage of pressurized air coming from the valve to the cylinder and to throttle the escape of air from the cylinder to the valve.

Double-acting piston with regulated speed¶

Pneumatic pistons typically move at fast speeds, the same fast speed of air as it enters and leaves the piston chambers.

Sometimes it is necessary to reduce the speed of the piston to avoid accidents or overly aggressive thrusts. For example, the opening and closing piston of a coach door must have a slow speed so as not to hit any passenger.

To achieve the effect of slow movement of the piston, two different schemes can be followed:

- Throttle the air inlet to the piston and leave the exhaust free.

This scheme causes problems because the air gradually enters the piston and generates pressure until the piston moves in jerks because there is no air in the opposite chamber. The movement is not fluid and the piston has little force in its movement.

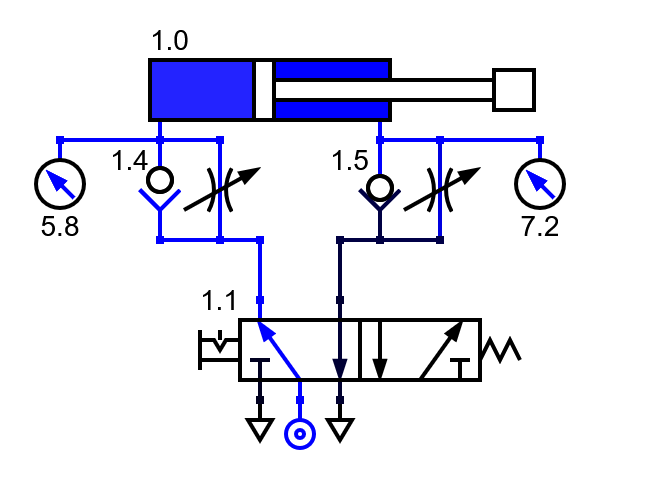

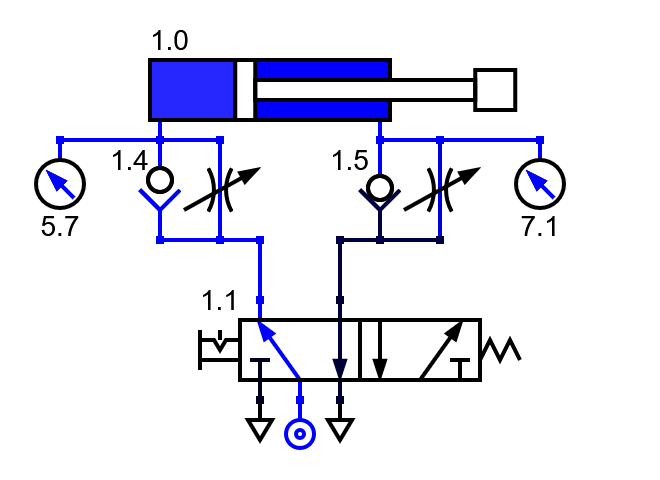

Double-acting piston with throttle valves at the air inlet.¶

- Throttle the air outlet to the exhaust and let pressurized air enter the piston without throttling.

This is the scheme that is used in practice because it ensures that the piston movement is carried out smoothly, without jerking and with all the force of the cylinder.

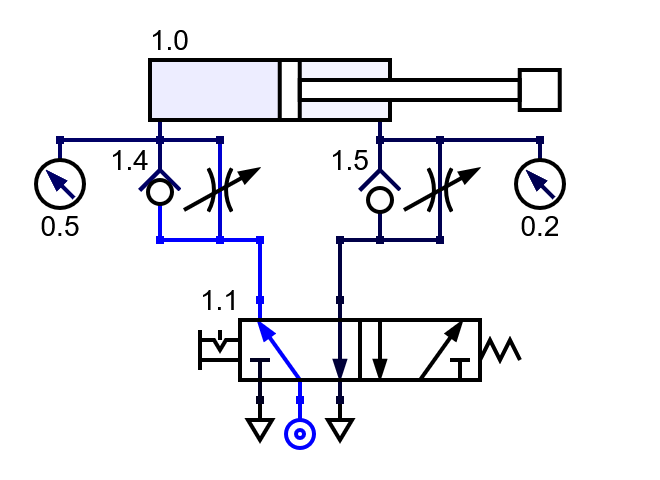

Double-acting piston with exhaust throttle valves.¶

Regulated speed operation¶

At first the cylinder is at rest with the rod inside. The right air chamber is filled with pressurized air (6 bar) exerting force so that the rod remains inside the cylinder:

Double-acting piston with rod inside.¶

Next, the 5/2 valve is activated and pressurized air begins to enter the left chamber of the cylinder. This air inlet is not throttled, so it enters with all possible speed.

There is still pressurized air in the right chamber of the cylinder, which goes out to the exhaust through the choke, so this chamber will empty slowly:

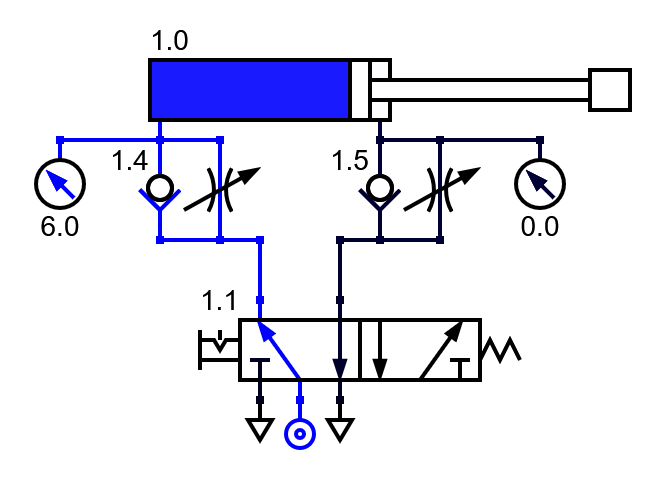

Double-acting piston with rod coming out in a regulated manner.¶

This slow emptying of the right chamber is what produces slow movement of the rod to the right.

Keep in mind that the pressure in the right chamber rises above the 6 bar of the compressor because its surface is smaller than that on the left side.

Since there is pressure in both air chambers, the piston is not free to move out of its corresponding position. So if we try to move the piston by hand we will find that it continues to move slowly outward without altering its path.

Finally, the right chamber will be completely emptied of air and the rod will come out all the way.

Double-acting piston with rod outside the cylinder.¶

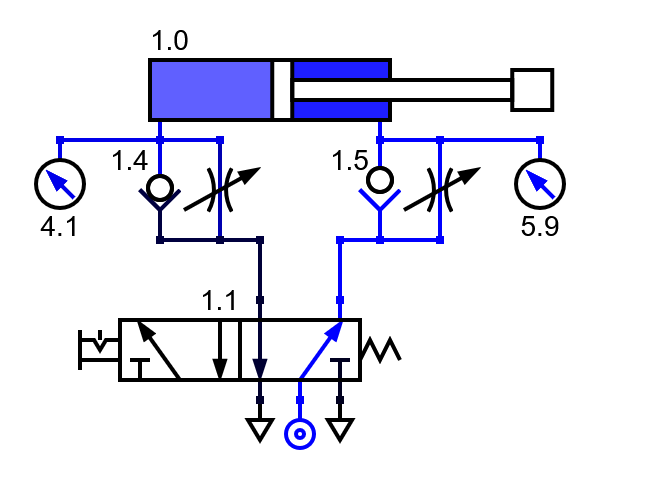

In the opposite movement, it is necessary for the pressure in the left chamber to drop below 6 bar, so that the right part of the cylinder has enough force to move it. Let's remember that the right camera has less strength than the left.

Double-acting piston with rod entering the cylinder.¶

Simulate in the following simulator the slow movements of the double-acting cylinder with air outlet restricted by a regulating valve. Remember to press the 's' key to make the simulation progress step by step:

Exercises¶

Draw the symbol of a non-return valve at rest.

Describes the operation of a non-return valve.

Draw the inside of the valve when it allows the pressurized air to pass through.

Draw the symbol for a choke valve.

Describe the operation of a choke valve. What is this valve for?

Draw the symbol for a one-way choke valve.

Describes the operation of a one-way throttle valve.

Draw the diagram of a double-acting cylinder with regulated air outlet speeds.

Draw and simulate the operation of the previous circuit in the simulator:

Explain the operation of the above circuit. Why does the rod move slowly?

Draw and simulate a pneumatic diagram of a double-acting cylinder that has the rod exit speed regulated, but that allows the rod to enter at maximum speed.