3. Pneumatic valves¶

Pneumatic valves are components that allow the passage of compressed air to be cut off or allow the passage of compressed air at will.

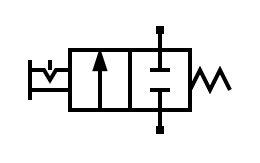

Below is the symbol of a normally closed 2/2 valve:

Valve 2/2 normally closed, at rest.¶

- The way to name a valve is as follows:

- First, the generic name Valve

- Second, the number of pathways or pipes through which the air can circulate. In this case there are 2 ways, one below and one above the valve body.

- Third, the number of positions of the pneumatic valve. They are the different boxes that the symbol has, in this case it has 2 positions.

Pilots are the methods used to move the valve. The valves have 2 pilot points, to activate them and to put them to rest. The previous valve is operated manually, with interlocking and goes to rest with the help of a spring.

2/2 valve¶

This valve is equivalent to a push-button faucet, like the one found in water fountains. It has two positions, rest and activated.

When the valve is at rest, air is shut off and no air flow is allowed through it. This is indicated by two "T", which represent the closed step.

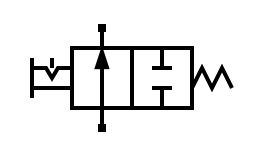

When the valve is activated, air can circulate between the two paths. This is indicated by an arrow that connects the lower track with the upper track:

2/2 valve normally closed, actuated.¶

Note

Although the arrow indicates the preferential flow of air from the bottom to the top, the valve is like an open faucet and also allows the air flow to circulate in reverse, from the upper path to the lower path.

In pneumatics, this valve is not widely used, because it only allows the passage of air in one direction and does not allow the return of air to empty the pneumatic cylinders.

In any case, we can find examples of the use of 2/2 valves in gas station tire inflation machines, in the triggers of air guns for cleaning or in the aerosol buttons.

2/2 valve and cylinder¶

To check the problems that a 2/2 valve presents when controlling a pneumatic cylinder, we are going to simulate its behavior with the simulator:

First we are going to select Simulate... Start from the menu to start the simulation.

- By actuating the 2/2 valve on the left, we allow the passage of air from the compressor to the cylinder and the cylinder rod will come forward completely.

- When valve 2/2 on the left is put to rest, the air passage from the compressor is closed, but the air remains stored in the cylinder, which remains extended.

- Now we are forced to operate the 2/2 valve on the right to allow the air in the cylinder to escape to the atmosphere and for the cylinder to return to its initial rest position.

This scheme is not very flexible because it requires activating two different valves to achieve the two cylinder movements. Despite this, we can see examples of its use in the cylinders that lift cars in mechanical workshops.

A problem with this scheme is that if we activate both valves at the same time, the air from the compressor will quickly escape into the atmosphere, quickly emptying the compressed air stored in the compressor.

Exercises¶

What is a pneumatic valve and what parts does it consist of?

How is a pneumatic valve named?

Draw a 2/2 valve at rest and another 2/2 valve actuated.

Explain in your words the operation of a 2/2 valve.

Why is the arrow on the tire symbol facing up? Is downward air passage allowed?

Write three examples of use of 2/2 pneumatic valves.

Draw in the following simulator the same circuit that can be seen in the simulator above. The simulation should work the same.

Explain in your words the operation of the previous circuit.

What will happen to the pneumatic cylinder in the previous circuit if we activate both valves at the same time? Simulate this case and explain the operation of the circuit.